If you’ve ever been to the R.W. Kern Center or taken a look around our website, chances are you’ve heard about our greywater system. It’s something we’re proud of and have spent a lot of time improving. We’ve just reached a major milestone in the life of this biophilic system (more on that later), and are inspired for a look back at how far we’ve come.

First, some background

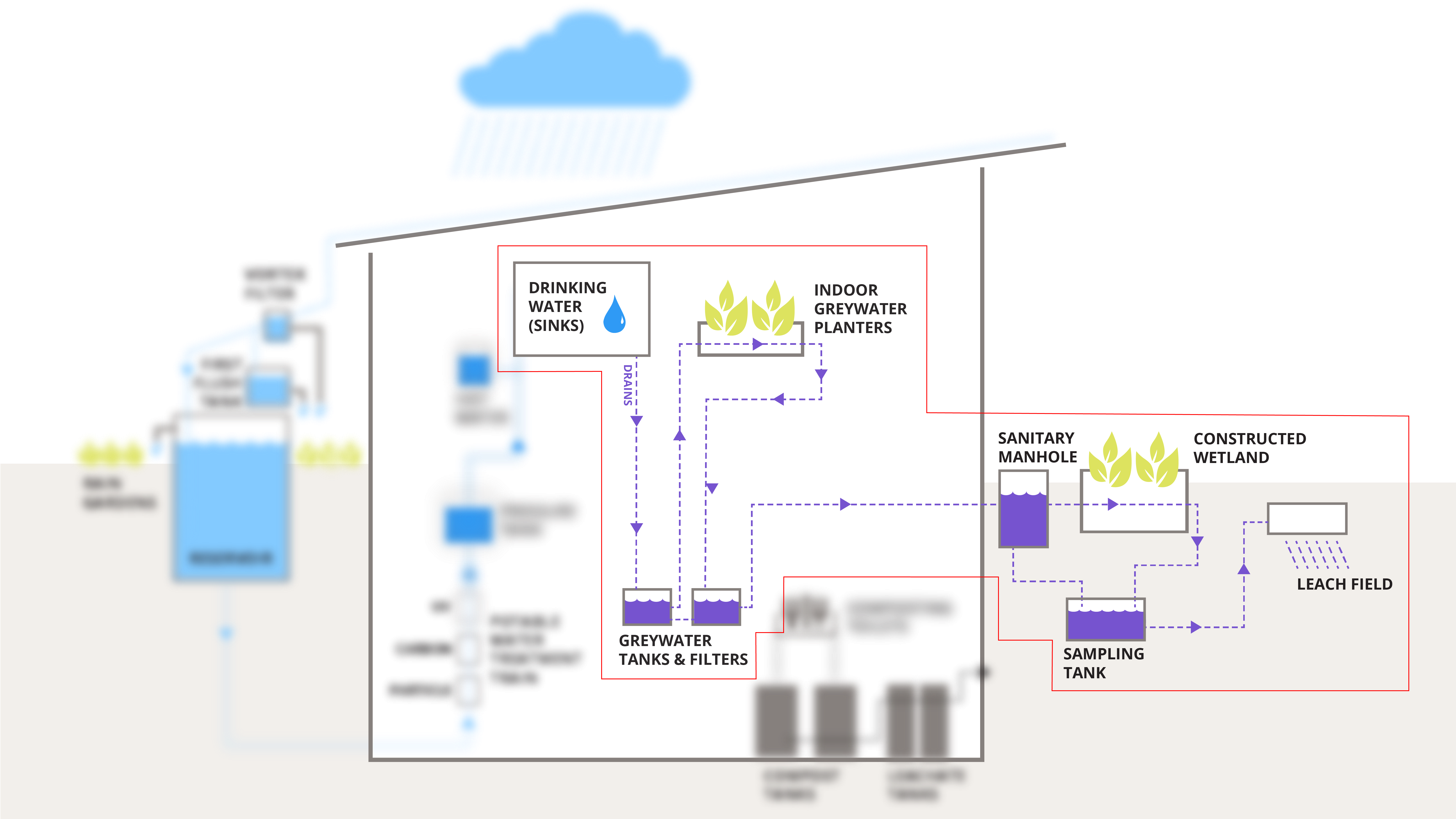

Greywater is wastewater, or used water, that has not come into contact with human waste. Greywater at the RWKC includes wastewater from sinks—restroom, café, kitchenette, and custodial floor sinks—as well as café drains and a water fountain. Because the RWKC uses waterless composting toilets, all of the wastewater produced by the building is greywater.

Unlike many buildings, the RWKC has no sewer connection or septic tank. Instead, our greywater is treated on-site before it is safely discharged back into the environment via a leach field. The end result is similar to a septic system, where liquid waste reenters the environment via a leach field.

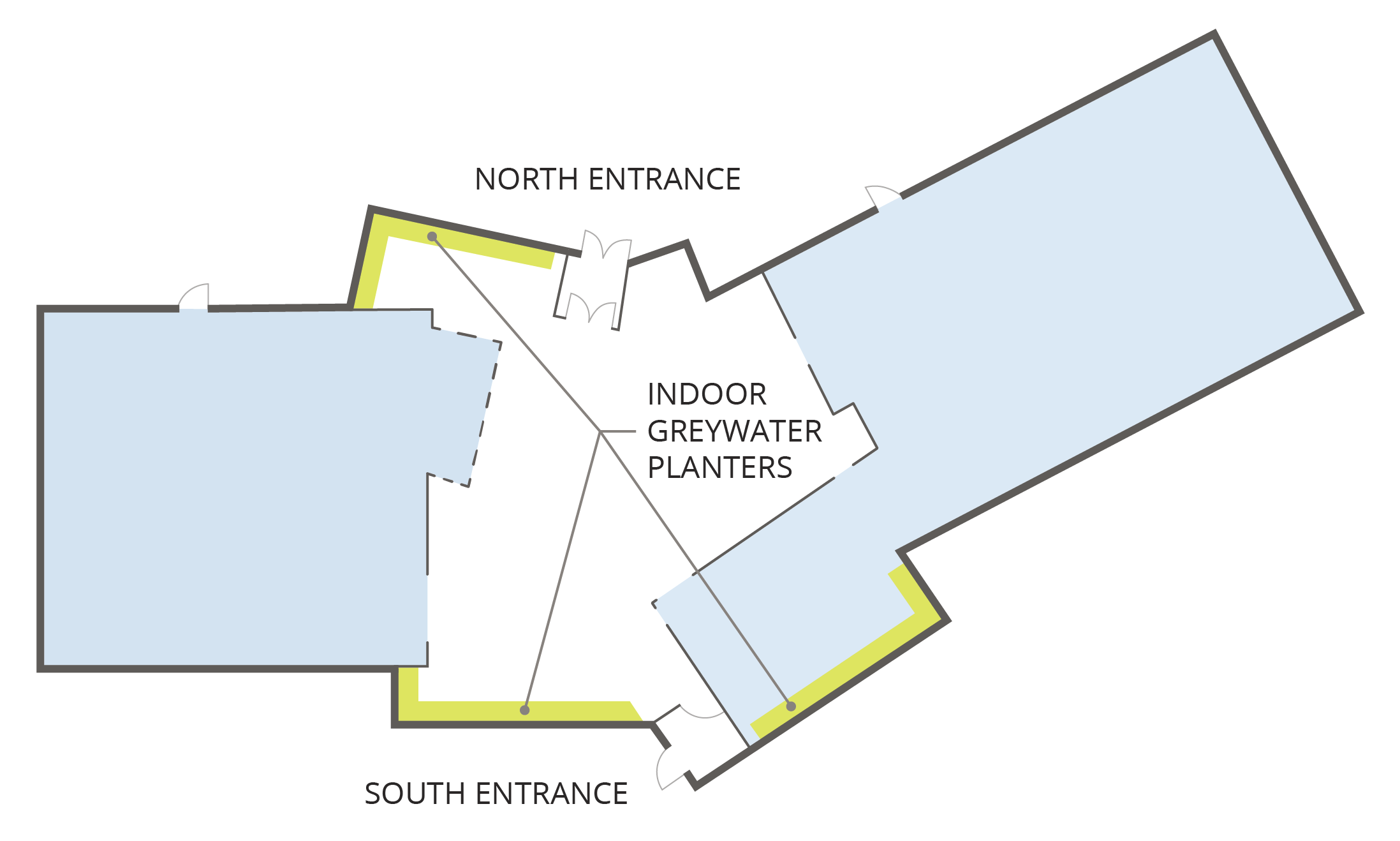

At the RWKC, greywater is collected and filtered through indoor planters in the building’s central common space and an outdoor constructed wetland (think: large concrete box filled with plants, soil, and gravel). First, greywater is pre-filtered—via a grease trap and high-tech pantyhose filter—and sent to a storage tank in the basement. From there it is pumped through irrigation hose in the indoor planters, where it filters through several feet of sand and soil and undergoes an aerobic treatment process to break down nutrients in the water. After this first phase, the greywater is collected in a second tank in the basement, where it is either recirculated through the indoor planters or pumped outdoors to a constructed wetland for further microbial action. Finally, water exiting the wetland enters a sampling chamber and is pumped to the disposal leach field, where treated water slowly seeps into the ground.

In the beginning…

The RWKC’s greywater treatment, collection, and disposal system was permitted as a site-specific pilot program by the Massachusetts Department of Environmental Protection (MassDEP) in February 2015. It wasn’t until the following year that our Clivus greywater treatment system was installed, just before the building’s ribbon cutting in April 2016. The system ran smoothly for the first few months. In June 2016, the Kern Kafé opened, and in the fall semester the RWKC lobby became a popular spot for students to study, assisted by a café beverage.

But there was a problem. A smelly problem. RWKC occupants began complaining of a foul odor permeating the building. Many suspected the stench (described as “sewage-like” or “swampy”) was coming from the composting toilets. To the surprise of many, the smell was actually coming from the greywater system.

The RWKC’s greywater system is lactose intolerant

Through heroic investigative efforts by staff, faculty, and students, the smell problem was pinned down in October 2016. Excess fats in the greywater system were clogging up the irrigation hoses and pipes. As a result, water was ponding in the lobby’s greywater planters, and the basement pumps were struggling to move water efficiently. But where were all these excess fats coming from?

Anyone who’s worked at a café knows that at the end of the day excess dairy, usually countertop carafes of milk and cream, must be disposed of. They’re simply poured down the drain, ending up in a sewage treatment plant. But in our system, all drains lead to one place: a holding tank in the basement. This meant that excess dairy, along with hot drainage water from the dishwasher and other greywater, was stewing for hours in a warm tank before being pumped to the indoor planters. This human-body-temperature water and dairy fat mixture was going rancid, stinking up the building. As this continued, the dairy began to solidify, clogging the pipes. By late November 2016, the entire system was completely clogged with dairy fats.

The quick fix was to flush the pipes with clean water to unclog the system. This was somewhat successful—the clogs were cleared enough that water could flow, but the rate at which water flowed significantly decreased. In early 2017, all of the irrigation pipes were replaced, as well as several inches of sand and soil. This removed the bulk of the dairy waste. The long-term solution was a new dairy composting program at the Kern Kafé. Café staff now place unused dairy into bins, which are taken to the Hampshire Farm to be gobbled up by the pigs.

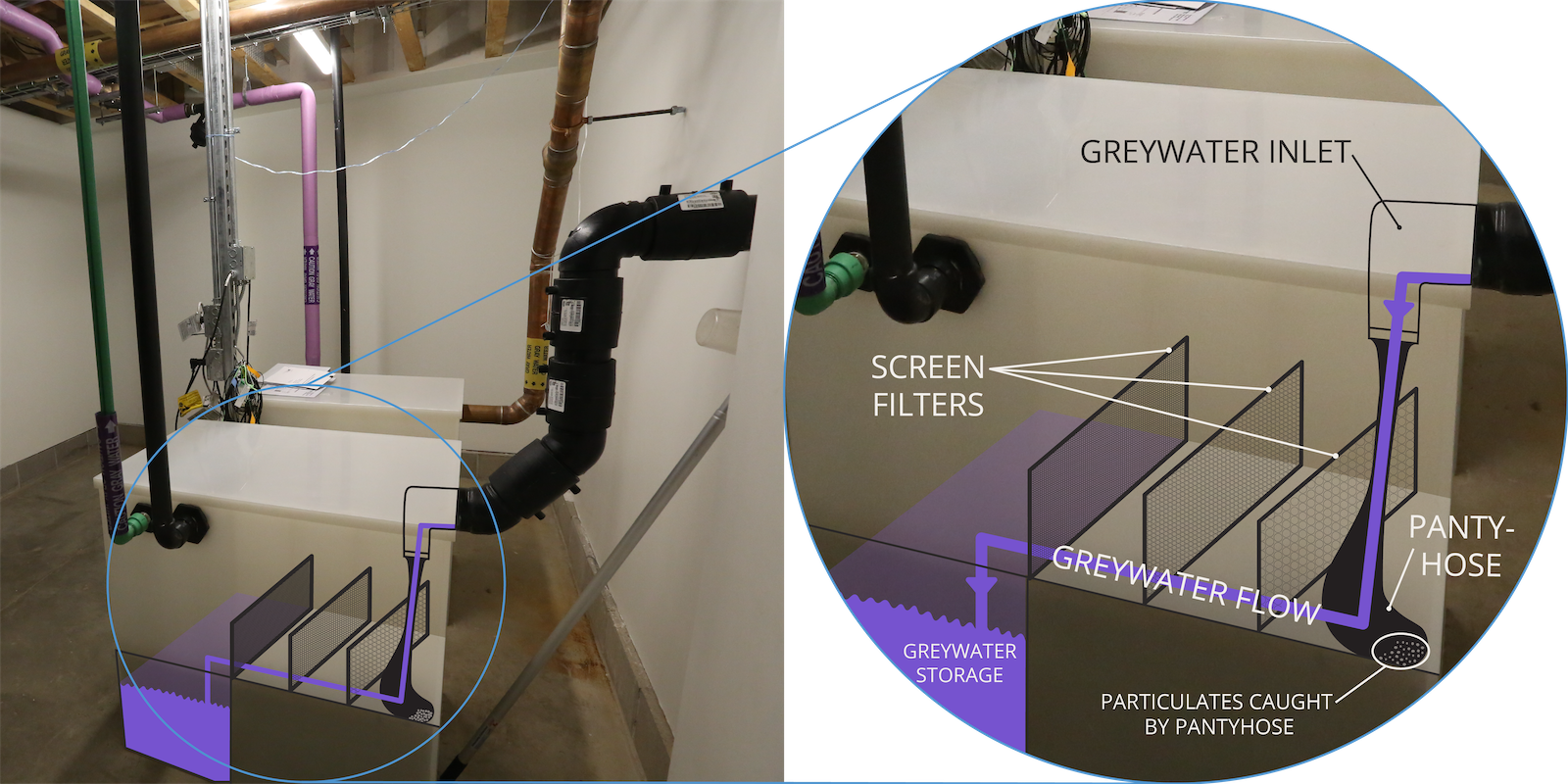

(Knee) High-tech

2017 was another eventful year in the life of our greywater system. After the dairy problem was solved and the greywater system was re-piped, our pipes began clogging again due to the large quantity of (non-dairy) solids entering the system from café effluent. The pumps we rely on to move greywater around the RWKC for treatment were working overtime, struggling to push past all the espresso grounds caught in the main disc filters. Greywater was ponding in the indoor planters, which brought back a swampy smell around the perimeter of the building. In February 2017, Clivus installed an ingenious solution: pantyhose. Nylon knee-highs effectively trap the espresso grounds that sneak through the café’s sink strainers and floor drains. They’re also cheap, can come from clothing recycling, and are easy to cut open to allow for composting of the solids inside.

Tiny Invaders

Related to the ongoing clogging issues, 2017 also brought an aphid infestation in two of the three indoor greywater planters. Aphids are tiny insects that appear in masses, feeding on plants and the nutrients plants need to survive. Aphids secrete a sticky honeydew, which attracts ants and other bugs. Aside from harming the health of our plants, the bugs made for a rather unpleasant café experience. We had to figure out how to eliminate them from our philodendron.

After months of trying to get rid of the aphids with pesticides, the solution was plant replacement. In January 2018, both south-facing planters were replanted with more pest-resistant species: jade succulents in one planter and anthurium in the other.

Hose vs. Pipe

Adding pantyhose to the inlets of each of the basement’s two greywater tanks in early 2017 decreased the maintenance required to clean out the clogged pumps and disc filters. But maintenance requirements were still higher than expected. Even after we implemented the pantyhose, it was difficult to remove the solids that already existed within the plumbing of our system, as was true when the café began composting leftover dairy.

All that said, our greywater system was functioning without any new issues until about halfway through 2018, when clogging and ponding again began occurring more regularly. This coincided with a shift in café management. During the staffing transition, the use of drop-in sink screens and a daily biologically active enzyme addition were discontinued. Café staff attempted to improve the system’s health by re-implementing these practices, but ultimately maintenance was still too high. At the end of 2018, we attempted to flush the system in the hopes of eliminating clogs. Hot water was pushed through all the pipes to dislodge any fats, oils, and grease (FOG), organic matter, or other solids in the pipes, drip emitters, and soil. Then the system was flushed with water and a biologically active FOG enzyme, which was left to work while the college closed for the winter break.

When the college reopened in January 2019, our system showed improvement for a few weeks—until the café reopened. Café staff were charged with flushing out the system multiple times a week, but even so, maintenance requirements were high. RWKC staff studied the soil in the planters. Some spots were overly saturated, while others were bone dry. This observation led us to believe that some of the irrigation hoses’ drip emitters, which release greywater to the planters at a steady rate, were permanently clogged. The emitters that weren’t clogged were working overtime to push water into the planters, resulting in some areas receiving more water than others.

At this point, we decided that the drip emitters had to go. We’d replace them with something new—HDPE pipes with open holes drilled in them, instead of tiny, easy-to-clog drip emitters designed to release water at a very specific flow rate. This would increase the flow of greywater into the planters and reduce the risk of clogging.

In August 2019, we replaced the drip tubing in the north planter as a trial run. This change seemed to do the trick. The soil in this planter was evenly saturated, and water seemed to be moving through the north planter much more easily. In January 2020, we made the same switch in one of the south planters, and have plans to replace the last planter soon.

For almost a year, our greywater system has been operating smoothly. With maintenance once a week to clean the greywater holding tanks in the basement and all the associated screens and filters, our system seems happy. Weekly maintenance is more than we expected when the system was designed, but if that’s what it takes to prevent bugs, smells, clogs, and other unpredictable messes, that is manageable for our Facilities staff.

Piloting Progress

As you can see, commissioning our greywater system has been no walk in the park. Operating an on-site greywater treatment system with a café introduces increased complexity to an otherwise well-established system. Our goal all along has been to simplify the system so it works with the least amount of regular maintenance. The past few years have required vigilance and trial and error to keep our system running effectively. We continue to work with the Kern Kafé to make sure that all our lessons learned get passed on to new staff to keep our pipes and the piggies happy.

As we mentioned in the beginning, our greywater system was approved by MassDEP as a pilot program. This means that there are certain monitoring requirements we have to meet to keep our system online. Every month Chris Chamberland, the engineer who designed and operates our system, visits the building to inspect the system and document his findings (thanks to him, we were able to piece together the story of our greywater system for this blog). Every three months, he tests the treated greywater to ensure it meets the standards outlined by MassDEP. Through all our system’s challenges and setbacks, we’ve been able to maintain the proper water quality required for discharge on site. And as of April 2020, we’ve been in operation for four years!

Spreading the news

We’re proud that our plant-based greywater treatment system has proven effective even in our challenging café environment, and love to offer guidance to designers, homeowners, and students. For a more detailed look, stay tuned for a timeline of the permitting and commissioning process for our system. And for more on the science behind the system, check out our own Claire Shillington’s paper in Water Environment Research.